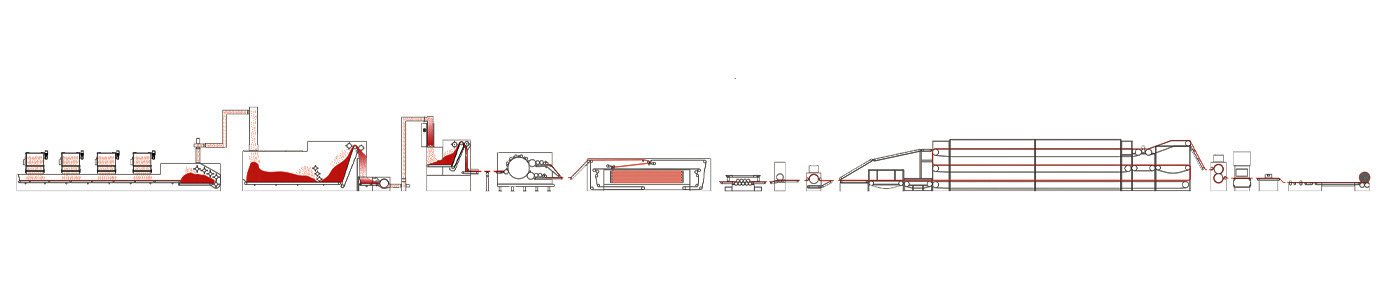

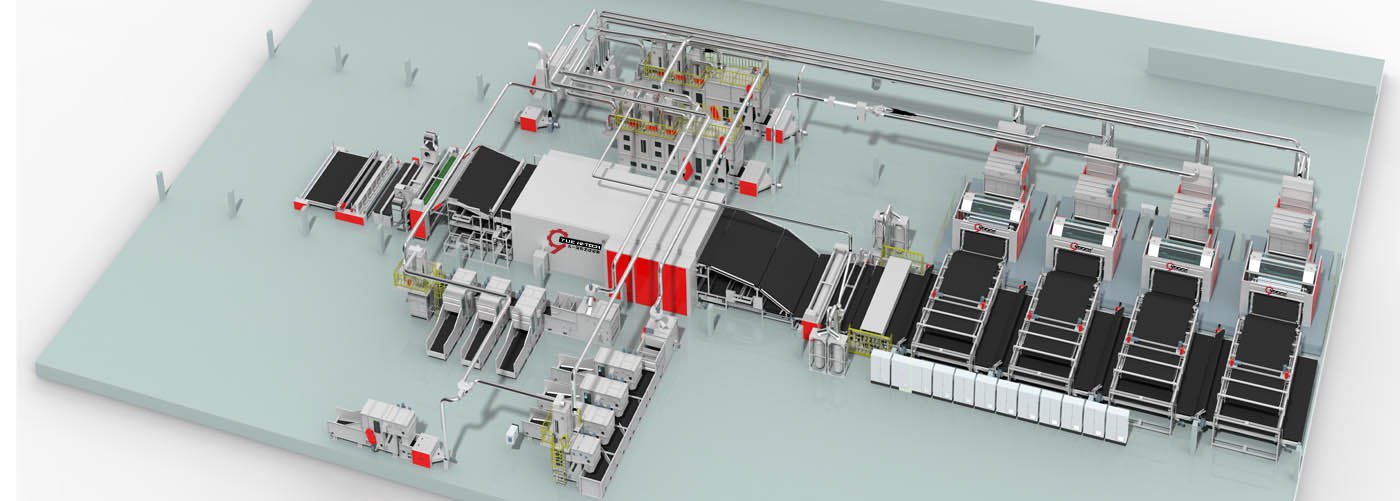

The spray bonded wading also called three-layer acrylic bonding wading designed to undergo chemical binding replacing the costly low melt fibers or any other bicomponent fibers. TUE HI-TECH offers a wider laying and spraying systems.

With the detailing of the carding and web formation process, upon requirements, series of carding and cross lappers are layered together in order to produce the felt of maximum densities. The spraying units are designed with the special nozzle systems in order to ensure the continuous spraying. Basically, the spray sections are either placed at the inlet of the first layer and the second layer. However, some customers do require the spraying at the second and third layer respectively.

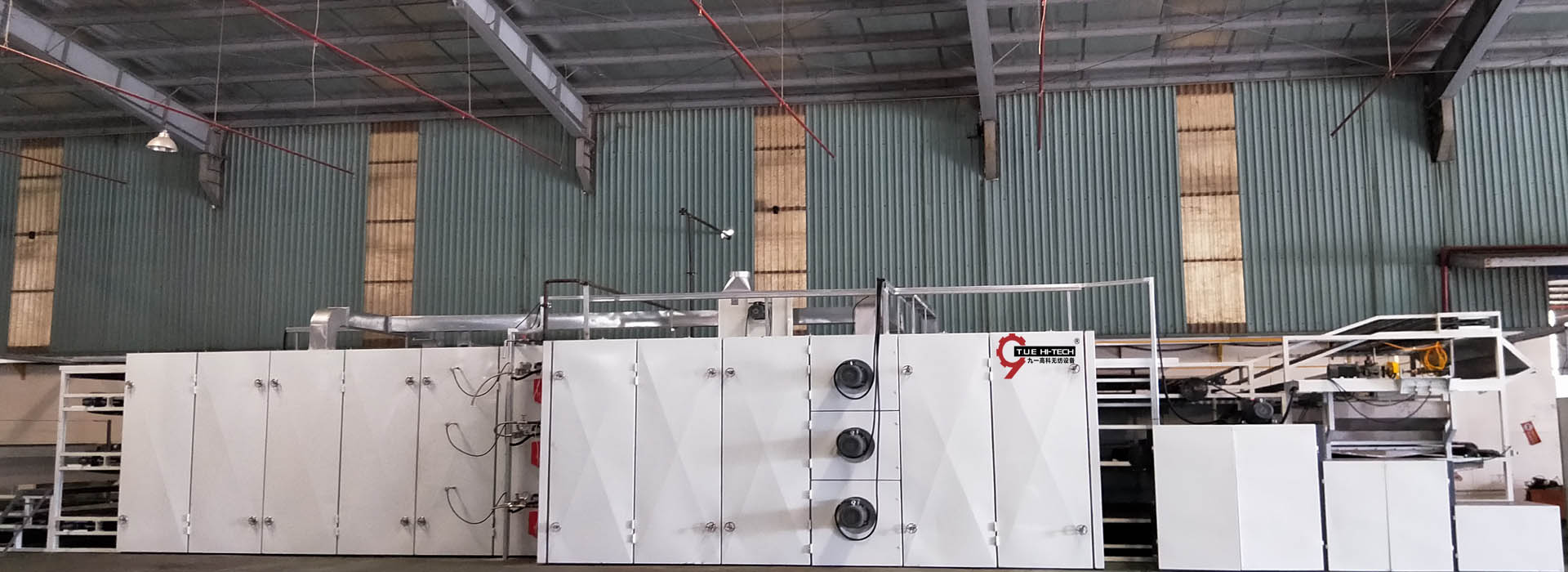

The machine is well developed with essential heating lengths and chambers to dry off the fabric that consists of the acrylic or any kinds of gluing. Such waddings are also widely used in filtration, padding or some household nonwoven applications.

TUE's Spray Bonded waddings

High loft wadding fabrics.

Heating for the oven can either be electric or gas heating.

Use of branded burners in the oven ensures uniformity of heat infeed.

Fabric layered with the acrylic or glue during bonding.

Energy Efficient- Brilliant heating technology.

Provided air cooling unit at the exit of the oven.